Complete Guide to Water Distillation: Process, Benefits and Applications

Introduction

Welcome to the ultimate deep dive into the world of distillation water! If you’ve ever wondered how that crystal-clear liquid in your bottle gets so pure, you’re in for a treat. Whether you’re a municipality looking to improve your water treatment processes, an engineer curious about the latest distillation equipment, or just someone who wants to know more about making distilled water at home, this guide has got you covered.

First things first: what exactly is distillation? Think of it as the superhero of water purification methods. It uses heat to transform water into vapor and then back into liquid, leaving impurities behind like a bouncer at an exclusive club. This process not only gives us distilled water, but it also opens up a world of benefits and applications that you might not even be aware of!

From industrial uses in pharmaceuticals and electronics manufacturing to everyday applications like using distilled water for humidifiers or in baby formula, distilled water is more versatile than you might think. But wait there’s more! We’ll also tackle some common misconceptions, such as the difference between tap and distilled water, and whether drinking distilled water is safe.

So grab your favorite beverage (preferably not from the tap), sit back, and let’s embark on this journey through the fascinating process of distillation. By the end, you’ll be equipped with all the knowledge you need to appreciate and perhaps even utilize the wonders of distilled water!

Understanding the Distillation Process

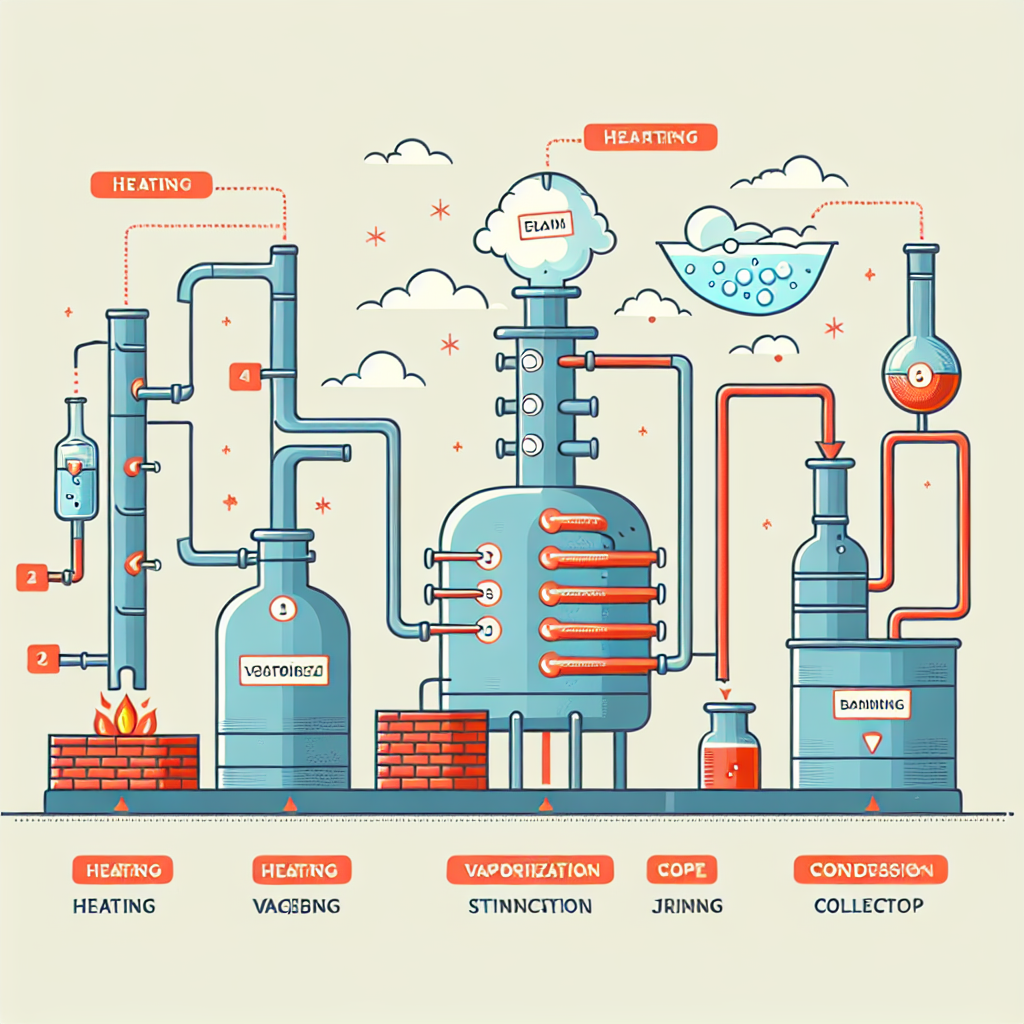

So, what exactly is the distillation process? Think of it as nature’s way of purifying water, but with a little help from science. At its core, distillation involves heating water to create steam and then cooling that steam back into liquid form. This nifty trick allows us to separate the pure water from impurities and contaminants.

Definition of Distillation

Distillation is a method used to separate components in a liquid mixture based on differences in their boiling points. When we talk about distillation water, we refer specifically to water that has undergone this process, resulting in what we call distilled water. This type of water is free from minerals, chemicals, and other impurities.

How Distillation Works

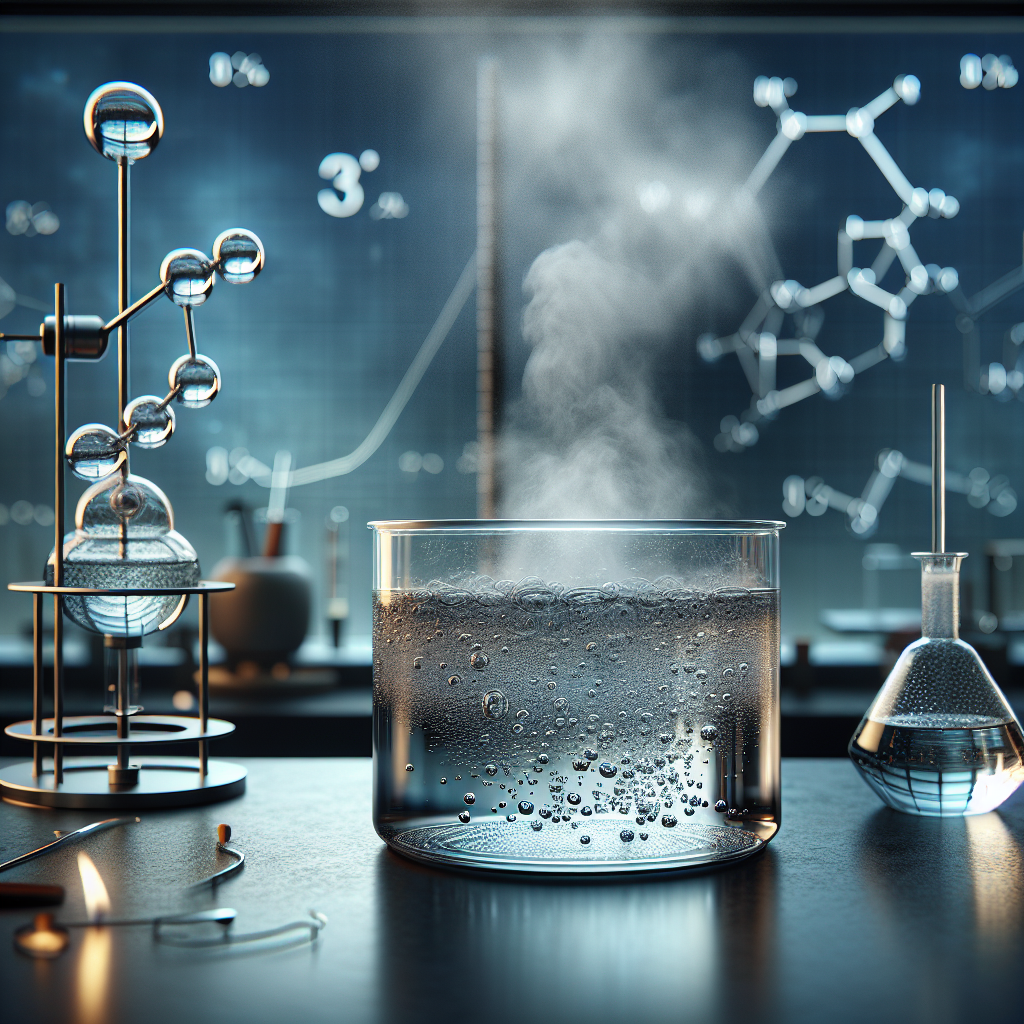

The magic begins when you heat the water. As it reaches its boiling point (100°C or 212°F), it transforms into steam. This steam rises and leaves behind any dissolved solids or contaminants think of it like a magician making the bad stuff disappear! The steam then travels through a cooling system where it condenses back into liquid form. Voilà! You’ve got yourself some fresh distilled water.

Chemistry of the Distillation Process

The chemistry here is pretty straightforward yet fascinating. Water (H2O) boils and turns into vapor while heavier impurities like salts and heavy metals remain in the original container. This process not only purifies the water but also alters its chemical composition slightly by removing those pesky minerals that can affect taste and quality.

Did you know? The distillation process can be performed using various types of equipment ranging from simple home setups to complex industrial systems designed for large-scale operations!

While distillation is an effective method for producing clean drinking water, it’s important to understand its advantages and disadvantages. For instance, while it removes most contaminants effectively, some argue that drinking distilled water exclusively may lead to mineral deficiencies over time due to its lack of essential minerals found in sources like spring or tap water.

The Cost of Distillation Process

If you’re considering how to distill water at home or on an industrial scale, keep in mind that costs can vary widely depending on the equipment used and volume produced. From DIY setups using pots and lids to sophisticated industrial distillers, there’s an option for every budget!

In summary, understanding the distillation process helps us appreciate how we can produce high-quality purified drinking water efficiently. Whether you’re creating distilled water for humidifiers or formulating baby formula, knowing how this process works will empower you to make informed choices about your hydration needs.

Types of Distilled Water

When it comes to distillation water, not all distilled water is created equal. Depending on the intended use, the type of distilled water can vary significantly. Let’s dive into the different types that you might encounter!

-

Lab-Grade Distilled Water

This is the crème de la crème of distilled water! Used in laboratories for experiments, this type must meet strict purity standards. Lab-grade distilled water undergoes rigorous testing to ensure it is free from contaminants, making it ideal for sensitive applications.

-

Bottled Distilled Water Brands

If you prefer convenience, bottled distilled water brands are widely available in stores. These products are typically used for drinking and cooking. However, be sure to check the label to ensure you’re getting quality distillation.

-

Homemade Distilled Water

Feeling adventurous? You can make your own distilled water at home! With simple equipment like a pot and a heat source, you can harness the power of the distillation process. Just remember: cleanliness is key to avoid any unwanted flavors!

-

Steam Distillation of Water

This method involves using steam to separate impurities from water. It’s commonly used in industrial settings but can also be applied at home with specific distillation equipment. The result? Pure H2O that’s ready for all your hydration needs!

Takeaway: Choosing the right type of distilled water depends on your needs be it lab use, cooking, or DIY projects at home. Understanding these types helps ensure you get the quality and purity you require!

Benefits of Using Distilled Water

So, why should you consider distillation water? Let’s dive into the benefits that make this liquid gold a must-have in various applications.

Purification and Safety Considerations

First off, distilled water is like the superhero of water purification. The distillation process effectively removes impurities, contaminants, and even those pesky minerals that can cause build-up in appliances. It’s essentially H2O stripped down to its purest form!

Did you know? Distilled water is often recommended for medical use due to its high purity level, making it safe for injections and other sensitive applications.

Distilled Water for Humidifiers

If you’ve ever dealt with a humidifier that sounds like a cat coughing up a hairball, you know the importance of using the right type of water. Using distilled water in humidifiers can prevent mineral deposits from forming inside the machine, keeping it running smoothly and ensuring cleaner air. It’s basically your humidifier’s best friend!

Use in Baby Formula and Medical Applications

When it comes to baby formula, parents often ask: “Is distilled water safe to drink?” Absolutely! In fact, many pediatricians recommend using distilled water for mixing baby formula because it eliminates harmful bacteria and chemicals found in tap water.

Advantages over Other Purification Methods (e.g., Reverse Osmosis)

You might be wondering how distilled water stacks up against other purification methods like reverse osmosis. While both methods are effective, the advantages of the distillation method include:

- No chemical additives: Unlike some purification processes, distillation doesn’t require any chemicals.

- Simplicity: The equipment needed for making distilled water at home is straightforward and easy to use.

- Comprehensive removal: Distillation efficiently removes a wider range of contaminants compared to many other methods.

The chemistry of the distillation process ensures that even volatile compounds are effectively separated from pure H2O.

Makeshift Solutions: Homemade Distilled Water

If you’re feeling adventurous or just want to save some bucks, you can always try making distilled water at home! All you need is some basic distillation equipment and a little bit of patience. Just think of it as your own science experiment but with way more practical applications!

In summary, whether you’re using it for health reasons or simply aiming for cleaner air with your humidifier, the benefits of using distilled water are hard to ignore. So next time you’re pondering over what type of water to use remember that when in doubt, go for distilled!

Applications of Distilled Water

When it comes to distillation water, its applications are as varied as a buffet at a food festival. From industrial uses to household hacks, distilled water is the unsung hero in many scenarios. Let’s dive into some of the most interesting and practical applications of this purified liquid!

Industrial Uses and Systems

In the industrial realm, distilled water plays a crucial role in ensuring product quality and equipment longevity. Here are some key areas:

- Cooling Systems: Many industries utilize distilled water in cooling towers to prevent mineral buildup that can lead to corrosion.

- Manufacturing: In processes like electronics manufacturing, where impurities can cause defects, distilled water is essential for rinsing components.

- Pharmaceuticals: The production of medicines often requires lab-grade distilled water to avoid contamination.

Pharmaceutical and Electronics Manufacturing Sectors

The pharmaceutical industry demands high purity levels; thus, the use of distilled water is non-negotiable. It’s used not only in drug formulation but also during cleaning processes for equipment. Similarly, in electronics manufacturing, using distilled water ensures that sensitive components remain free from harmful minerals and contaminants.

Household Uses and DIY Projects

If you think distilled water is just for laboratories, think again! Here are some fun household applications:

- Making Distilled Water at Home: With the right distillation equipment, you can create your own supply right in your kitchen. It’s like being your own mad scientist!

- Humidifiers: Using distilled water in humidifiers prevents mineral buildup and keeps your device running smoothly while also improving air quality.

- Irrigation Systems: For those who love gardening, using distilled water can help keep plants healthy by avoiding chlorine and other chemicals found in tap water.

- Beverage Preparation: Ever thought about using distilled water for your coffee or tea? It can enhance the flavor by removing unwanted minerals!

- Baby Formula: Many parents opt for distilled water when preparing baby formula to ensure their little ones are getting only the purest ingredients.

Takeaway: The versatility of distilled water makes it invaluable across various sectors from industrial applications to everyday household uses. Understanding these applications not only helps you appreciate its importance but also empowers you to make informed choices about its use!

The Cost of the Distillation Process

When it comes to distillation water, understanding the cost of the distillation process is crucial for municipalities, engineers, and manufacturers alike. It’s not just about boiling water and collecting steam; there’s a financial aspect that can make or break your budget.

Initial Investment in Equipment

First up, let’s talk about the initial investment in distillation equipment. Depending on your needs, this can range from a few hundred dollars for a basic home setup to thousands for industrial-grade systems. If you’re considering large-scale production, expect to shell out for:

- Distillation units: These vary in size and efficiency.

- Heat sources: Gas vs. electric options can affect your bottom line.

- Cooling systems: Essential for efficient condensation.

- Piping and storage tanks: Necessary for handling distilled water safely.

Operational Costs for Large-Scale Production

The operational costs can be a real doozy! Here are some factors that contribute to ongoing expenses:

- Energy consumption: Distilling water requires significant energy, especially if you’re running multiple units.

- Maintenance: Regular upkeep is necessary to ensure peak performance of your distillation systems.

- Sourcing raw water: Depending on local regulations and availability, this can add additional costs.

Bottled vs. Homemade Options: Cost Analysis

If you’re weighing the options between buying bottled distilled water or making it at home, here’s a quick breakdown:

| Bottled Distilled Water | Homemade Distilled Water | |

|---|---|---|

| Cost per gallon | – (varies by brand) |

The Cost of the Distillation Process

.10 – The Cost of the Distillation Process

.50 (after initial setup) |

| Sustainability | Poor (plastic waste) | Good (reusable equipment) |

| Taste Consistency | High (brand-dependent) | Variable (depends on equipment) |

The choice between bottled and homemade distilled water ultimately depends on your specific needs and budget. If you’re looking for convenience and consistency, bottled might be your jam. However, if you’re all about saving bucks while ensuring quality, making distilled water at home could be the way to go!

The Environmental Impact of Large-Scale Commercial Operations

When it comes to distillation water, the process is not just about making pure H2O; it’s also about understanding the environmental footprint of large-scale commercial operations. As industries ramp up production to meet demand, they often overlook the ecological implications tied to their water purification methods.

Let’s dive into the nitty-gritty of how these operations impact our planet.

Sustainability Considerations in Production Methods

The distillation process itself can be energy-intensive. Traditional methods require significant heat, often generated from fossil fuels, which contributes to greenhouse gas emissions. However, modern innovations are paving the way for more sustainable approaches:

- Solar Distillation: Utilizing solar energy can drastically reduce carbon footprints.

- Waste Heat Recovery: Capturing and reusing heat from industrial processes can improve efficiency.

- Advanced Distillation Equipment: New technologies are being developed that use less energy without compromising on quality.

The Impact on Local Resources and Communities

Large-scale distillation operations can also strain local water resources. As industries withdraw vast amounts of groundwater for their processes, surrounding communities may face:

- Water Scarcity: Reduced availability of clean water for local residents and agriculture.

- Aquifer Depletion: Long-term extraction can lead to irreversible damage to local ecosystems.

- Pollution Risks: Improper disposal of waste products from distillation can contaminate nearby water sources.

Tangible Takeaway: It’s crucial for companies engaged in water purification especially those using the distillation method to adopt more eco-friendly practices. This not only helps protect our planet but also ensures a sustainable supply of distilled water for future generations.

Distilled vs. Purified Water: Key Differences and Similarities

- < li>Differences in Production Methods

li>< li>Nutritional Content Comparison

li>< li>User Preferences and Misconceptions

li> ul> section >

Conclusion

h2 > section >

source https://www.waterandwastewater.com/complete-guide-distillation-water-process-benefits/

No comments:

Post a Comment