UV LED vs. UV Lamp Disinfection: A Comprehensive Comparison

The ongoing evolution of disinfection methods has been propelled into the limelight as public health demands have surged in response to the global pandemic. Among various technologies available, ultraviolet (UV) disinfection has gained popularity due to its efficacy in deactivating pathogens. Within the domain of UV disinfection, two prominent technologies have emerged: UV LEDs and traditional UV lamps. Both solutions offer unique benefits and challenges, leading various institutions, governments, and industries to evaluate their respective organizational needs.

This article will explore the differences, similarities, advantages, and disadvantages of UV LED and UV Lamp disinfection systems.

Understanding UV Disinfection

The Basics of UV Light

Ultraviolet (UV) light is part of the electromagnetic spectrum, existing just beyond the visible light range. It can be divided into three primary bands:

-

UVA (320 – 400 nm): Often associated with tanning and skin damage, UVA has the lowest energy of the three bands but can still affect living organisms over prolonged exposure.

-

UVB (280 – 320 nm): This range is shortwave UV light that causes sunburn and is more germicidal than UVA, but it still does not reach the energy levels required for effective disinfection.

- UVC (200 – 280 nm): This range encompasses the most germicidal wavelengths. UVC light is most effective at inactivating bacteria, viruses, and other pathogens by disrupting their DNA or RNA structure, rendering them non-infectious.

Both UV LEDs and UV Lamps primarily utilize UVC light in their disinfection processes, but they differ in their operational technologies and applications.

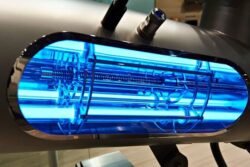

Types of UV Lamps

Traditional UV disinfection lamps can be broadly categorized into three types:

1. Low-Pressure Mercury Vapor Lamps

These lamps are the most common type used in water and air disinfection. They emit UVC light at a peak wavelength of 254 nm, which is highly effective at deactivating pathogens.

2. Medium-Pressure Mercury Vapor Lamps

These lamps produce a broader spectrum of UV radiation, which includes UVC, UVB, and visible light. They are often utilized in large-scale applications, such as wastewater treatment plants, due to their higher intensity and efficiency.

3. Pulsed Xenon Lamps

These lamps generate high-intensity pulses of UV light in a very short duration. They can produce a broad spectrum but are more commonly used in air and surface disinfection applications.

What Are UV LEDs?

UV LEDs (light-emitting diodes) are solid-state devices that emit UV light when an electric current passes through them. They offer specific benefits over traditional UV lamps:

-

Energy Efficiency: UV LEDs consume less power compared to UV Lamps, leading to lower operational costs.

-

Longevity: UV LEDs have a longer lifespan, often exceeding 25,000 hours when compared to traditional UV lamps, which usually last around 10,000 hours.

-

Instant Start-Up: Unlike traditional UV lamps, which require a warm-up period to achieve full intensity, UV LEDs provide immediate illumination, making them suitable for applications requiring rapid disinfection.

-

Compact Size: The design of UV LEDs allows for more compact systems, which can better integrate into various settings.

- Less Heat Generation: UV LEDs produce less heat than traditional lamps, minimizing the need for additional cooling systems in some applications.

Direct Comparisons: UV LEDs vs. UV Lamps

Efficacy

UV Lamp Efficacy:

- Traditional UV lamps emit UVC light predominantly at 254 nm, which has been proven effective against a wide variety of pathogens.

- Depending on the type of lamp, intensity and spectrum may vary, which can influence disinfection efficacy.

UV LED Efficacy:

- UV LEDs offer specific wavelengths, typically around 260-280 nm.

- Recent research indicates that certain wavelengths may lead to different efficacy levels against various pathogens, and ongoing improvements in LED technologies are expected to enhance their performance.

Application Range

Use Cases for UV Lamps:

- Water Treatment: UV lamps are widely used for disinfecting drinking water, where their capacity to treat large volumes in one go has proven effective.

- Surface Disinfection: Various spheres of industries incorporate UV lamps for disinfection, such as healthcare, food processing, and air purification systems.

Use Cases for UV LEDs:

- Narrow-spectrum applications often leverage UV LEDs, particularly in small-scale operations like HVAC systems and certain sterilization uses (e.g., sterilizing medical equipment).

- The compact nature of UV LEDs has facilitated their growth in portable disinfection devices and consumer products.

Energy Consumption

UV Lamps:

- Traditional UV lamps require more energy than LEDs to operate, primarily due to the inefficiencies in converting electrical energy into UV radiation.

UV LEDs:

- UV LEDs are far more energy-efficient, consuming up to 80% less energy than standard traditional UV lamps, which is particularly beneficial with rising electricity costs.

Lifespan and Maintenance

UV Lamps:

- Standard UV lamp lifespan ranges from 9,000 to 15,000 hours, after which efficiency decreases, causing the need for timely replacement.

- Maintenance may involve checking ballasts and other components. Replacing lamps can also be inconvenient in large systems.

UV LEDs:

- UV LEDs have a much longer life-span of 25,000 to 50,000 hours, significantly reducing maintenance costs.

- They require less frequent replacement, making them ideal for time-sensitive applications.

Cost Considerations

Initial Investment:

- UV lamps are generally less expensive upfront compared to UV LEDs, making them appealing to budget-conscious organizations.

Long-term Costs:

- The lower energy requirements and longer lifespans of UV LEDs lead to reduced operational costs over time, counterbalancing their initial investment.

Safety Considerations

UV Lamps:

- Mercury elements in traditional UV lamps pose a risk during disposal and environmental contamination. Additionally, exposure to UVC light can be hazardous to skin and eyes, necessitating proper shielding measures.

UV LEDs:

- UV LEDs do not contain hazardous chemicals, resulting in safer handling. However, they also require adequate safety precautions, as direct exposure can be harmful.

Environmental Impact

UV Lamps:

- The mercury content in UV lamps necessitates special disposal procedures to prevent environmental hazards.

UV LEDs:

- The solid-state nature of LEDs provides a more environmentally friendly option for disinfection, as they do not contain harmful materials.

Innovations and Future Prospects

Advances in UV LED Technology

-

Tuning Wavelengths: New studies are focusing on developing UV LEDs that can be tuned for specific wavelengths, optimizing them for targeting various pathogens more efficiently.

-

Integration with IoT: The future of disinfection may involve integrating UV LEDs into Internet of Things (IoT) platforms that can monitor disinfection cycles, adjust settings automatically, and notify users of abnormalities or maintenance needs.

- Sustainability Frameworks: As consumers increasingly seek eco-friendly products, innovations will focus on improving the energy efficiency and environmental credentials of UV LED disinfection systems.

Hybrid Systems

The future may see the rise of hybrid systems that utilize both UV LEDs and traditional UV lamps, allowing users to harness the strengths of both technologies while mitigating their limitations. Such systems could deliver flexible disinfection solutions tailored to specific settings or applications.

Conclusion

The race between UV LEDs and traditional UV lamps for supremacy in disinfection technologies presents a compelling discussion for industries, healthcare facilities, and consumers alike. While traditional UV lamps have been reliable workhorses in the field for many years, the advancements in UV LED technology reflect a significant evolution towards more energy-efficient and effective disinfection systems.

Ultimately, choosing between UV LEDs and UV lamps depends on specific factors, including application requirements, budget constraints, energy consumption preferences, and safety considerations. Organizations must carefully evaluate their customization options and align those with their operational needs to ensure maximum efficacy in disinfection.

As we look to the future, innovations in UV disinfection technology will likely bridge the gap between these two formidable systems, providing safer, cleaner environments for all. Whether through collaborative approaches or the emergence of new technologies, it is clear that the landscape of disinfection will continue to evolve, driven by both necessity and advancement.

The post UV LED Vs UV Lamp Disinfection appeared first on Water & Wastewater.

source https://www.waterandwastewater.com/uv-led-vs-uv-lamp-disinfection/

No comments:

Post a Comment