Filtration Systems: An In-Depth Exploration

Introduction

In today’s world, the importance of clean resources is paramount. Filtration systems are central to ensuring the purity of air, water, and various other substances critical to both living organisms and industrial processes. Over the past few decades, advances in technology and a deeper understanding of materials have led to significant improvements in filtration systems, enhancing their efficiency, sustainability, and utility.

Historical Background of Filtration Systems

The concept of filtration has been around for thousands of years, dating back to ancient civilizations. The Egyptians, for instance, used sand filtration systems to purify water around 2,000 BCE. The Greeks and Romans further improved these systems, with Roman aqueducts often incorporating sand and gravel filtration methods.

In the 19th century, the importance of filtration was highlighted during the cholera outbreaks, leading to the development of sand filters, which significantly improved public health. By the 20th century, the industrial age had prompted the development of various filtration systems tailored for different needs, from HVAC (Heating, Ventilation, and Air Conditioning) systems to chemical processes in manufacturing.

Types of Filtration Systems

Modern filtration systems are diverse and designed to meet specific needs across different sectors. Below are some of the primary types of filtration systems:

-

Water Filtration Systems:

- Reverse Osmosis: A process that involves forcing water through a semi-permeable membrane to remove ions, molecules, and larger particles. It is highly effective in desalinating seawater and purifying drinking water.

- Activated Carbon Filters: Utilize a bed of activated carbon to remove contaminants and impurities, relying on adsorption. They are widely used for water purification and air filtration systems.

- Ultrafiltration: Employs a semi-permeable membrane that removes fine particles, colloidal particles, and macromolecules, leaving behind clean water.

- Sediment Filtration: The simplest form involving a mechanical filter that removes larger particles from water, like sand, silt, and dirt.

-

Air Filtration Systems:

- High-Efficiency Particulate Air (HEPA) Filters: Capable of capturing 99.97% of particles that are 0.3 microns or larger, playing a vital role in cleanrooms, hospitals, and household air purifiers.

- Electrostatic Filters: Use electric charges to attract and capture dust and other airborne particles.

- UV Filters: Employ ultraviolet light to destroy airborne pathogens and microorganisms, enhancing air quality.

- Industrial Filtration Systems:

- Oil Filtration: Involving the removal of contaminants from oils in machinery and automotive engines, crucial for maintaining engine health and efficiency.

- Gas Filtration: Used in refineries and chemical plants to purify gases, protecting equipment and ensuring product quality.

- Bag and Cartridge Filters: Commonly used in manufacturing to separate dust and particles from air or liquid streams.

Applications of Filtration Systems

The multifaceted nature of filtration systems allows them to be implemented across various industries and applications:

-

Healthcare: In hospitals, filtration systems are vital in maintaining sterile environments. HEPA filters are extensively used to filter air, and water filtration is critical to ensure safe sterilization processes.

-

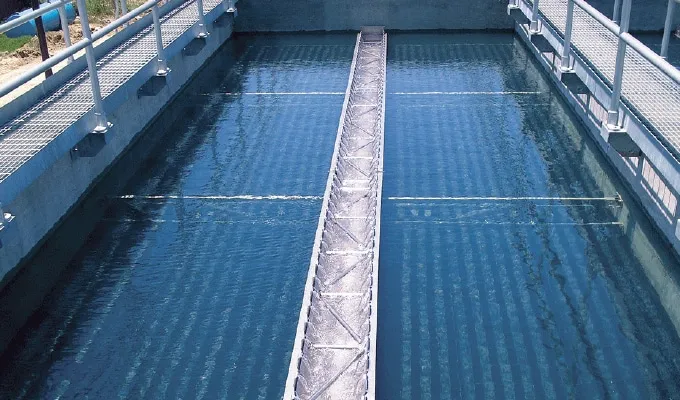

Municipal Water Treatment: Filtration is a fundamental step in water treatment plants to provide safe, potable water to the public. Advanced filtration systems remove pathogens, chemicals, and particulates.

-

Industrial Manufacturing: Many manufacturing processes require filtration to maintain product quality, remove unwanted byproducts, and ensure the safety of operations. Examples include the filtration of lubricating oils and hydraulic fluids.

-

Food and Beverage Industry: Involves filtration to ensure the purity of products, whether it’s purifying ingredients, managing effluents, or ensuring the quality of the final product.

- Environmental Protection: Filtration systems aid in pollution control by filtering emissions from industrial processes, thus reducing the environmental footprint.

Technological Advancements in Filtration Systems

Recent years have seen remarkable advancements in filtration technology:

-

Nanotechnology and Materials Science:

- The development of nanofiber membranes increases efficiency in filtering fine particles due to their small pore sizes and large surface areas.

- Advanced materials like graphene-enhanced filters offer superior strength and permeability.

-

Smart Filtration Systems:

- Integration of IoT (Internet of Things) technology allows for real-time monitoring and control of filtration systems, optimizing performance and maintenance schedules.

-

Energy Efficiency:

- Energy consumption is a significant concern; hence, new designs aim to reduce the energy footprint of filtration processes. For example, rotary drum filtration systems have been optimized for energy efficiency in industrial settings.

- Sustainable and Eco-friendly Solutions:

- Biodegradable filters and recyclable materials are being developed to minimize waste and environmental impact.

Challenges Facing Filtration Systems

Despite advancements, filtration systems face several challenges:

-

Maintenance and Longevity: Filters can become clogged or wear out over time, necessitating regular maintenance and replacement.

-

Cost: High initial costs for advanced systems and the continual cost of filter replacements can be prohibitive for some organizations.

-

Material Limitations: Some filters may have limitations based on the materials they can filter or the environment in which they operate.

-

Disposal and Environmental Impact: Used filters can become an environmental concern if not disposed of properly, especially those containing hazardous materials.

- Adaptability and Scalability: Designing systems that can be easily adapted or scaled up for different applications remains a complex task.

Future Directions of Filtration Systems

The future of filtration systems looks promising, with research continually pushing boundaries:

-

Advanced Material Development: Research is ongoing into new materials that could offer unprecedented levels of filtration at lower costs and environmental impact.

-

Integration with Renewable Energy: Systems that integrate directly with renewable energy sources will likely reduce operational costs and improve sustainability.

-

Decentralized Water Systems: With the increasing need for clean water, localized, small-scale systems could provide efficient solutions for remote or resource-limited areas.

- Enhanced Digitalization: Further integration of AI (Artificial Intelligence) and machine learning could offer predictive maintenance and performance optimization.

Conclusion

Filtration systems are indispensable to modern life, affecting virtually every industry and playing a critical role in health and environmental sustainability. As technological advancements continue to evolve, so too will the capabilities of filtration systems, crafting a path toward cleaner, safer, and more sustainable living conditions across the globe. The combined efforts of scientific research and industry innovation promise a future where filtration is not only more effective and accessible but also more attuned to the dynamic requirements of our world.

The post Filtration Systems appeared first on Water & Wastewater.

source https://www.waterandwastewater.com/filtration-systems/

No comments:

Post a Comment