Sludge treatment is integral to wastewater management and crucial for protecting public health and the environment. As communities and industries generate wastewater, treating this water to remove contaminants before it’s returned to the environment is essential. The sludge that results from wastewater treatment contains a variety of substances, including organic matter, pathogens, chemicals, and heavy metals. Treatment and proper disposal or reuse of this sludge are vital to ensure environmental safety and resource recovery.

The process of sludge treatment involves several stages. Initially, primary sludge treatment focuses on separating solids from the liquid in the wastewater. Following this, secondary treatment methods further reduce organic material and contaminants. Advanced stages include sludge digestion, wherein microorganisms break down organic matter, reducing volume and destroying pathogens. After digestion, sludge dewatering removes excess water, making the sludge more straightforward to handle and transport. Finally, the treated sludge can be disposed of safely or repurposed in applications such as soil amendment, following strict regulations and compliance measures to prevent environmental harm.

Key Takeaways

- Sludge treatment is critical for environmental protection and resource recovery.

- The process includes multiple stages: primary and secondary treatment, digestion, dewatering, and disposal or reuse.

- Strict regulatory adherence is required to manage the risks associated with treated sludge.

Overview of Sludge Treatment in Wastewater

Sludge treatment is a critical component of the wastewater treatment process, focusing on managing the byproduct of cleaning water used by communities and industries.

Importance of Sludge Treatment

Sludge treatment is essential for reducing the environmental impact of wastewater. It transforms the semisolid byproduct, often called ‘biosolids,’ into a state that is easier to handle, transport, and dispose of. Proper treatment ensures that harmful pathogens and chemicals are neutralized, significantly minimizing risks to public health and the environment.

Critical Principles of Sludge Management

Safe handling and disposal: Sludge management involves ensuring that the sludge is handled and disposed of in a manner that safeguards human health and complies with environmental regulations.

Volume reduction: One primary goal is to reduce the volume of sludge, which reduces disposal costs and makes the sludge more straightforward to process.

Stabilization: Sludge stabilization reduces odors and decomposes organic matter. Methods like anaerobic digestion, which produces biogas that can be converted into energy, are utilized.

Dewatering: Another critical principle is dewatering, which reduces the sludge volume by removing a significant portion of the water content. Techniques include sand beds, centrifugation, and filter presses.

Sludge in water treatment refers to the residual, semisolid material produced as a byproduct during wastewater treatment. The ultimate goal is to convert this waste product into a form that can be easily managed, safely applied to land or disposed of in a landfill.

Primary Sludge Treatment

In wastewater treatment, primary sludge treatment is a critical phase where solids are separated from the liquid waste. This process reduces the volume of wastewater that needs to be treated in subsequent stages and concentrates solids for further processing.

Primary Settling Tanks

Primary settling tanks, known as primary clarifiers, play a vital role in wastewater treatment. They are designed to exploit gravity, allowing particulate matter to settle while the clearer effluent flows out for secondary treatment. Here, the term primary sludge emerges, referring to the mixture of solids that settle to the bottom of the tanks.

Operation:

- Flow rate: Optimized to reduce turbulence and enhance settlement.

- Design: Typically rectangular or circular to promote even distribution of sludge.

Benefits:

- Volume reduction: The efficiency of primary settling tanks helps reduce sludge volume by 30-40%.

- Organic matter removal: Approximately 25-35% of the incoming organic matter is captured as sludge.

Thickening: After collection, primary sludge is usually thickened before further treatment or disposal. Thickening is a process that increases the solids content of the sludge, making it easier and more cost-effective to handle. Thickening methods can include gravity thickeners, which allow more solids to settle, and mechanical thickeners, which use devices like centrifuges or belt presses to concentrate the solids.

Understanding the effectiveness of primary sludge wastewater treatment and thickening techniques is essential for designing and operating efficient wastewater treatment systems.

Secondary Sludge Treatment

In wastewater management, secondary sludge treatment represents a critical phase where organic matter is decomposed, and the resultant semisolid waste is further processed for either disposal or reuse.

Activated Sludge Process

The activated sludge process is a fundamental secondary treatment method involving aeration tanks. Here, aeration encourages the growth of microorganisms that consume organic matter. This process can typically be segmented into four stages: aeration, settling, waste sludge removal, and returning activated sludge to the aeration tank.

- Aeration: Air or oxygen is introduced to mix with the wastewater, fostering aerobic digestion by bacteria.

- Settling: After aeration, the mixture moves to a secondary clarifier, where biomass settles out.

- Waste Sludge Removal: A portion of the settled sludge, known as excess activated sludge, is removed from the process.

- Returning Activated Sludge: Some settled sludge is recirculated to the aeration tank to maintain active biomass.

Secondary Clarifiers

Secondary clarifiers are tanks built for one critical function: to allow the biomass formed in the activated sludge process to settle. This settling process separates the clarified effluent from the mixture. They function through two integral processes:

- Settling: The decreased kinetic energy allows the activated sludge to settle out of the treated water.

- Decanting: The clear water from the top is decanted and often subjected to further treatment or discharged if it meets regulatory standards.

Efficient secondary clarifiers are pivotal as they reduce the volume of sludge to be handled in subsequent treatment steps and enhance the overall quality of the treated wastewater.

Sludge Digestion

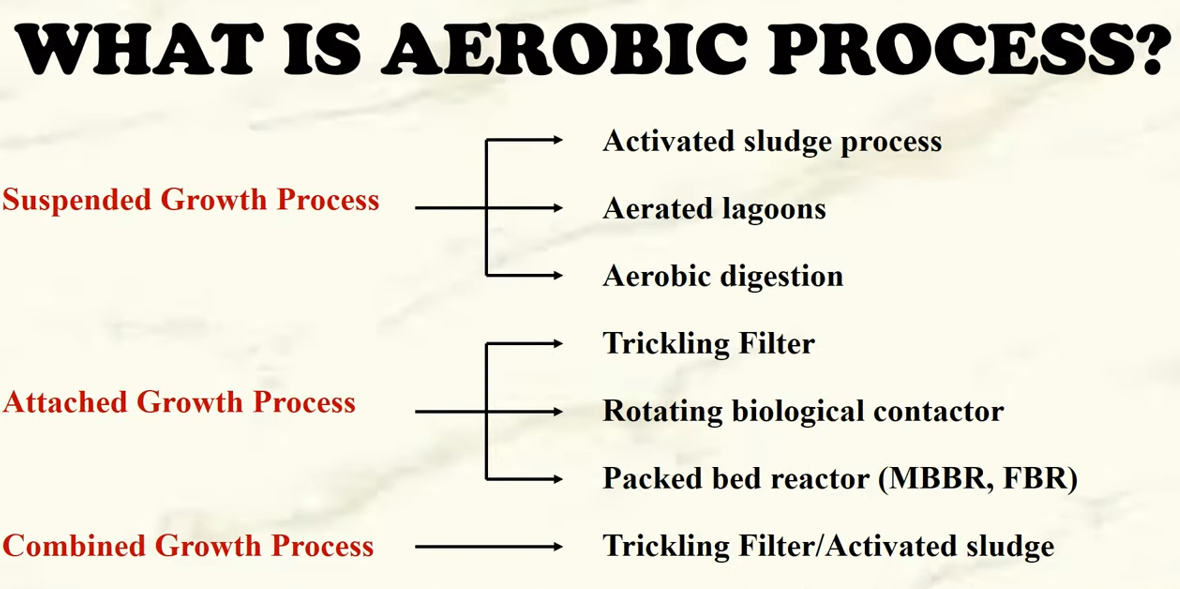

Sludge digestion is a critical process in wastewater treatment, where organic matter in the sewage sludge is broken down by microbial activity. Primarily, there are two types of digestion processes: aerobic and anaerobic.

In aerobic digestion, microorganisms consume organic matter in the presence of oxygen. This method is energy-intensive due to the need for oxygen supply, resulting in a less odorous end product. It suits smaller-scale operations or where nitrogen removal is also required.

Conversely, anaerobic digestion is more common for treating the sludge from sewage. Without oxygen, anaerobic bacteria decompose organic solids, producing methane and carbon dioxide as byproducts. This process happens in digesters maintained at certain temperatures, ranging from 15 to 60 days at 68 to 131°F (Penn State Extension). The methane produced can be harnessed to generate energy, offering renewable energy and increasing the process’s sustainability.

Benefits of sludge digestion include volume reduction, pathogen destruction, and the possibility of utilizing the byproducts, such as biogas and nutrient-rich solids that can be applied as fertilizers.

The components of the digestion process include:

- Pre-treatment: Removal of inorganics and thickening of sludge.

- Digestion: Biological decomposition of organic solids.

- Post-treatment: Stabilization, dewatering, and preparation for disposal or use.

Monitoring and controlling the conditions within the digesters is essential to promote the most efficient breakdown of solids and biogas generation. The choice between aerobic and anaerobic digestion methods depends on various factors, including plant size, sludge characteristics, and resource recovery objectives.

Sludge Dewatering

In the treatment of wastewater, the process of sludge dewatering is a critical step. It involves reducing the water content of the sludge to minimize its volume, which subsequently lowers the costs associated with sludge disposal or further processing. The procedure is a physical operation that separates liquids from solids.

Methods of Sludge Dewatering:

- Centrifugation: Utilizing centrifugal force to separate sludge into solid and liquid components.

- Belt Filter Presses: Conveying sludge through rollers to apply pressure and squeeze out the water.

- Filter Presses: Employing pressure to push water through a filtration system, leaving solids behind.

- Drying Beds: Allowing water to evaporate or percolate naturally from sludge through a sand and gravel layer.

Key Considerations:

- Solid Content: The efficiency of dewatering is influenced by the initial solid content of the sludge.

- Chemical Conditioning: Polymers can enhance dewatering by binding solid particles and improving separation.

- Operational Cost: Equipment choice impacts the overall expense; energy-intensive methods like centrifugation may incur higher costs.

The selection of the dewatering method depends on various factors, including the nature of the sludge, the desired moisture content after dewatering, and cost implications. Effective dewatering can significantly reduce the quantity of wastewater sludge, facilitating more cost-effective handling and transport.

It remains essential for treatment facilities to optimize the dewatering process, aligning with the goals of efficiency and environmental compliance. Advances in technology continue to improve dewatering operations, allowing for more effective and sustainable wastewater management.

Sludge Disposal and Management

Proper sludge disposal and management are critical in wastewater treatment to minimize environmental impacts and comply with regulations. The selection of a sludge disposal method depends on factors such as the characteristics of the sludge, environmental policies, and available facilities.

Land Application

The land application involves spreading treated sludge and biosolids onto agricultural fields to utilize its nutrient content. This method can enhance soil fertility and structure. However, it requires careful monitoring to prevent heavy metal accumulation and to protect groundwater from contamination.

Landfill Disposal

When sludge is deemed unsuitable for land application due to high concentrations of pollutants, landfilling is often employed. While this is a practical solution, it presents long-term concerns over land usage and potential leaching of contaminants.

Incineration

Incineration of sludge significantly reduces its volume and can potentially recover energy through combustion. The incineration must be carefully controlled to minimize the emission of pollutants and to conform to air quality standards.

Composting

Composting is an aerobic process stabilizing sludge by converting it into a humus-like material. Not only does this make the sludge safer for land application, but it also recycles organic matter, offsetting the need for synthetic fertilizers.

Sludge Treatment Technologies

Effective sludge treatment is crucial for any sludge treatment facility, as it ensures environmental compliance and resource recovery. Technological advancements have led to more efficient sludge removal and processing in wastewater treatment.

Innovative Dewatering Methods

Dewatering is an essential step in sludge treatment, aiming to reduce sludge volume for disposal. An example of advanced technology in this area involves thermal drying, where sludge is subjected to high temperatures, effectively evaporating moisture and dramatically reducing sludge weight and volume. This method enhances the ease of sludge handling and transportation. Moreover, centrifugation is a mechanical dewatering technique that employs centrifugal force to separate sludge solids from liquid, leading to a drier sludge product.

Enhanced Digestion Techniques

Anaerobic digestion is a widely used process that breaks down organic matter in sludge without oxygen, producing biogas. Specific enhancements to this process have emerged, such as temperature-phased digestion, where sludge is first digested at a thermophilic range (higher temperatures) and then at a mesophilic range (lower temperatures). This two-phase approach can increase the efficiency of biogas production. Alternatively, adding co-digestion materials, like fats, oils, and grease, can supplement the organic content of the sludge, further boosting biogas yields while reducing the volume of residual sludge.

Regulations and Compliance

Effective sludge treatment is regulated by stringent local and global standards, ensuring environmental and health safety. These regulations are vital in minimizing wastewater sludge’s impact on the environment and public health.

Local and Global Standards

Municipalities and nations enforce specific regulations for sludge treatment and disposal. For example, the Environmental Protection Agency (EPA) regulates sewage sludge in the United States under Title 40 CFR Part 503, setting forth pollution standards, management practices, and operational criteria. Similarly, international standards, such as those set by the European Union, stipulate acceptable levels of heavy metals and pathogens to ensure that sludge can be safely applied to land as fertilizer or disposed of.

- Standards Include:

- Nutrient content

- Pathogen reduction

- Heavy metals concentration

- Odor management

Environmental and Health Safety

The main goal of effluent and sludge regulations is to protect human health and the environment. This includes the reduction of harmful pathogens, toxic organic compounds, and heavy metals that may be present in untreated sludge. For example, specific pathogen treatment processes must be followed, and regular monitoring of sludge quality must be maintained to ensure compliance with regulatory frameworks.

- Safety Measures Must Address:

- Pathogen levels: To minimize potential health risks.

- Pollutant concentrations: To prevent environmental contamination.

- Odor and vector attraction: To reduce nuisances and possible health concerns.

The treatment and disposal of sludge is a critical process in wastewater management. It requires adherence to established local and global guidelines to protect ecosystems and public health.

Frequently Asked Questions

As global water demands increase, understanding the methods of sludge treatment in wastewater is crucial for sustainability and health.

What methods are employed to remove sludge from wastewater systems?

Wastewater systems rely on several methods to remove sludge, including gravity sedimentation, flotation, centrifugation, and filtration. These processes separate solids from the water, enabling further treatment or disposal of the sludge.

What constitutes an effective sludge treatment strategy?

An effective sludge treatment strategy reduces sludge volume, stabilizes organic materials, and sanitizes pathogens to minimize environmental impact. It often includes thickening, digestion, dewatering, and thermal processes to produce a manageable and safe end product.

Which sludge treatment process is most prevalent in waste management?

Anaerobic digestion is the most prevalent sludge treatment process in waste management, transforming organic matter in sludge into biogas, which can be used for energy and leaving a nutrient-rich material that can be safely disposed of or used as fertilizer.

Can you explain the stages of sludge treatment in primary wastewater treatment?

During primary wastewater treatment, sludge is predominantly processed through screening and sedimentation. Screenings remove large solids, whereas sedimentation allows sludge to settle, which is then scraped for further treatment.

What are the different technologies available for wastewater sludge management?

Technologies for wastewater sludge management include anaerobic digestion, aerobic digestion, composting, incineration, and advanced thermal processes like pyrolysis and gasification. Each technology is designed to stabilize the sludge and reduce potential hazards.

What examples illustrate the practical application of sludge treatment processes?

The practical application of sludge treatment processes can be seen in facilities that integrate anaerobic digestion to produce biogas or in regions with water scarcity, where treated sludge is used for land application to improve soil health and reduce the need for synthetic fertilizers.

The post Sludge Treatment in Wastewater: Enhancing Efficiency and Reducing Environmental Impact appeared first on Water & Wastewater: Your Source for Water Clarity.

source https://www.waterandwastewater.com/sludge-treatment-in-wastewater-enhancing-efficiency-and-reducing-environmental-impact/?utm_source=rss&utm_medium=rss&utm_campaign=sludge-treatment-in-wastewater-enhancing-efficiency-and-reducing-environmental-impact

Centrifugal Pumps:

Centrifugal Pumps: Positive Displacement Pumps:

Positive Displacement Pumps: Grinder Pumps:

Grinder Pumps:

Peristaltic Pumps

Peristaltic Pumps

Principles of Wastewater Treatment

Principles of Wastewater Treatment Conversely, anaerobic treatment operates in the absence of oxygen. Methanogenic bacteria thrive in these conditions, decomposing organic matter and producing methane and carbon dioxide as byproducts. Anaerobic processes are well-regarded for treating high-strength wastes and their ability to generate bioenergy. They typically precede aerobic treatment in a multi-stage treatment process to optimize the degradation of organic pollutants and the elimination of nitrogen and phosphorus.

Conversely, anaerobic treatment operates in the absence of oxygen. Methanogenic bacteria thrive in these conditions, decomposing organic matter and producing methane and carbon dioxide as byproducts. Anaerobic processes are well-regarded for treating high-strength wastes and their ability to generate bioenergy. They typically precede aerobic treatment in a multi-stage treatment process to optimize the degradation of organic pollutants and the elimination of nitrogen and phosphorus.