PFAS Capital Improvement Plan: A Comprehensive Guide for Municipal Leaders and Environmental Engineers

Introduction

As we advance further into 2025, the regulatory landscape surrounding per- and polyfluoroalkyl substances (PFAS) has become one of the most pressing issues for municipalities and water treatment facilities. PFAS, commonly referred to as “forever chemicals,” pose significant health risks and environmental challenges, necessitating robust and proactive management strategies. A well-devised PFAS Capital Improvement Plan (CIP) stands at the forefront of these strategies, enabling municipalities to secure funding, improve public health outcomes, and ensure compliance with evolving regulations.

In this article, we will delve into the critical components of a PFAS Capital Improvement Plan, the driving regulations, technologies for remediation, and best practices for successful implementation. This comprehensive overview responds to the urgent needs of plant operators, municipal directors, and design engineers seeking actionable insights into PFAS management.

Understanding PFAS and Their Regulatory Landscape

What Are PFAS?

PFAS are a large group of synthetic chemicals used in manufacturing a variety of consumer products for their water- and grease-resistant properties. Commonly found in firefighting foams, nonstick cookware, and stain-resistant treatments, these substances are persistent in the environment and human body, leading to a buildup that raises environmental and health alarms.

Regulatory Developments

As of July 2025, the U.S. Environmental Protection Agency (EPA) has ramped up its oversight regarding PFAS, implementing stricter guidelines across the nation. In 2024, the EPA established a Maximum Contaminant Level (MCL) for two key PFAS compounds—PFOA and PFOS—set at 4 parts per trillion (ppt). Following these regulations, states have begun drafting their own response plans, further emphasizing the urgency for municipalities to act.

The User Intent: Why a PFAS Capital Improvement Plan?

The intent behind searching for a PFAS Capital Improvement Plan is typically informational and problem-solving. Municipal leaders may seek strategic insights to develop plans that address regulatory compliance and public health concerns while effectively allocating resources. Design engineers, on the other hand, may focus on technological solutions and best practices for treatment methodologies.

Developing a Robust PFAS Capital Improvement Plan

1. Assessing Current PFAS Levels

Initial Monitoring and Testing

The first step in developing a CIP is to conduct thorough testing of drinking water sources, wastewater effluents, and stormwater systems for PFAS contamination. According to industry analysis from 2024, nearly 70% of water systems in the U.S. have detected at least one PFAS compound. This provides a foundational understanding of current levels and aids in identifying sources of contamination.

- Recommended Actions: Collaborate with accredited laboratories for comprehensive water quality assessments and annual monitoring schedules.

2. Establishing Regulatory Compliance

Navigating Federal and State Regulations

Staying updated with the latest regulations from the EPA and state agencies is critical for effective planning. The regulatory environment can differ significantly across regions, necessitating tailored approaches that account for local requirements.

- Compliance Checklist:

- Review federal and state guidelines.

- Identify potential funding sources for compliance initiatives.

- Integrate regulatory benchmarks into existing monitoring protocols.

3. Prioritizing Remediation Technologies

Emerging Solutions for PFAS Treatment

Numerous technologies have emerged for PFAS remediation. Here are some leading examples:

-

Granular Activated Carbon (GAC): Highly effective for large volume treatment in municipal water systems. Studies show GAC can remove up to 90% of PFAS compounds when appropriately designed.

-

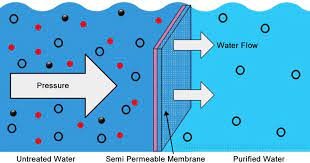

Anion Exchange Resins: These have performed well in pilot studies, showing removal efficiencies exceeding 95% for certain PFAS.

-

Advanced Oxidation Processes (AOP): Innovative techniques like AOP can degrade PFAS contaminants but remain under scrutiny for cost-effectiveness.

- Next Steps: Conduct pilot tests to evaluate which technology best fits the specific PFAS profile of your municipality while considering operational costs and maintenance.

4. Financing the PFAS Capital Improvement Plan

Identifying Funding Opportunities

Budgeting for PFAS-related infrastructure improvements can be daunting. However, funding avenues such as the EPA’s Water Infrastructure Finance and Innovation Act (WIFIA) loans and state-specific funding allocations can help alleviate fiscal pressures.

- Funding Strategy:

- Apply for federal and state grants to support project costs.

- Consider public-private partnerships (PPPs) for shared financial responsibility.

- Develop a transparent financial model to assess long-term impacts versus upfront investments.

5. Community Engagement and Public Awareness

Building Trust Through Transparency

Engaging the community should be an integral part of the PFAS Capital Improvement Plan. Public awareness campaigns can help inform citizens about the risks associated with PFAS and the measures being undertaken to address them.

- Engagement Tactics:

- Host public forums to discuss plans and gather feedback.

- Utilize social media and local news outlets to share regular updates.

- Develop informative brochures that clarify both the risks of PFAS and your municipality’s proactive steps.

Implementing and Monitoring the Plan

1. Phased Implementation Strategy

Establish a clear timeline for the rollout of the CIP, complete with benchmarks and performance indicators. A phased approach enables municipalities to adapt and respond to emerging data and regulatory shifts.

2. Regular Evaluation and Reporting

An effective CIP cannot remain static. Implement a continuous improvement process including:

- Annual Assessments: Regularly review water quality data and operation costs.

- Stakeholder Reports: Keep the community informed of progress, challenges, and future actions.

Conclusion

As we navigate the complexities surrounding PFAS contamination, a robust PFAS Capital Improvement Plan becomes pivotal in safeguarding public health and ensuring environmental safety. By assessing current conditions, prioritizing remediation technologies, securing funding, and engaging the community, municipalities can effectively tackle the challenges posed by these persistent pollutants.

The time to act is now. With evolving regulations and increased public scrutiny, municipalities that proactively address PFAS through comprehensive Capital Improvement Plans will not only enhance compliance but also foster community trust and improve overall public health outcomes. Embracing these strategies is not merely advisable; it is essential for the sustainable management of our water resources in 2025 and beyond.

source https://www.waterandwastewater.com/pfas-capital-improvement-plan/