Foam Fractionation for PFAS: The Future of Water Treatment

Introduction

The contamination of drinking water sources and groundwater with per- and polyfluoroalkyl substances (PFAS) has become one of the most pressing environmental challenges of the 21st century. These persistent chemicals, often dubbed "forever chemicals," have been linked to a range of health issues, including reproductive and developmental problems, liver damage, and immune system dysfunction. As of 2025, regulatory measures have tightened significantly worldwide; states are establishing maximum contaminant levels (MCLs) for PFAS, urging municipal authorities and water treatment facilities to adopt innovative solutions to eliminate these toxins from water supplies. Among these solutions, foam fractionation has emerged as a promising method for effectively treating PFAS-contaminated water. This article delves into the intricacies of foam fractionation, its application for PFAS removal, and the implications for water treatment professionals and municipal planners.

Understanding PFAS and Their Environmental Impact

What Are PFAS?

PFAS are a group of over 4,700 synthetic compounds characterized by carbon-fluorine bonds, which confer exceptional stability and resistance to degradation. They are commonly found in various consumer products, including non-stick cookware, waterproof clothing, and firefighting foams. Due to their widespread use and persistence in the environment, PFAS have been detected in water, soil, and even within the human body.

The Health and Regulatory Landscape

Research has shown that PFAS exposure is associated with various health risks. For instance, studies indicate that certain PFAS compounds can disrupt endocrine functions and are linked to cancers and liver damage. In response to growing public health concerns, the U.S. Environmental Protection Agency (EPA) updated its health advisory levels for PFAS in drinking water in 2023, proposing a Maximum Contaminant Level Goal (MCLG) of 0.004 ppt for PFOA and 0.02 ppt for PFOS. As of July 2025, many states are enacting stricter regulations, compelling water treatment facilities to seek effective removal techniques.

The Mechanism of Foam Fractionation

What is Foam Fractionation?

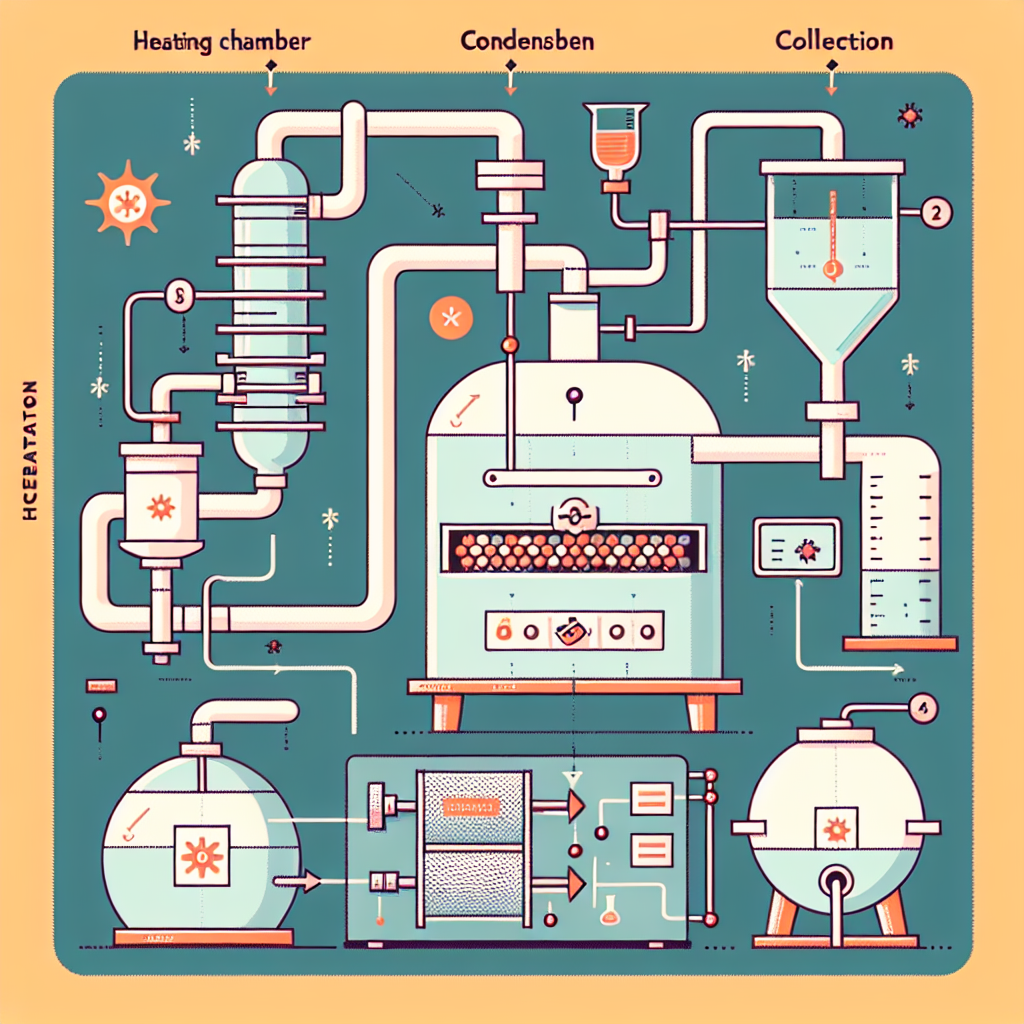

Foam fractionation is a separation process that exploits differences in surface activity to concentrate and remove pollutants from water. The technique involves injecting air into a contaminated water stream, leading to the formation of bubbles. As PFAS and other surface-active compounds attach to the soap-like bubbles, they rise to the surface, forming a foam layer that can be removed, leaving the cleaner water below.

How Foam Fractionation Works

-

Air Injection: Compressed air is introduced into a water stream, facilitating bubble formation.

-

Bubble Formation: The physical and chemical properties of PFAS allow them to adsorb onto the surface of the bubbles.

-

Foam Separation: The bubbles rise to the surface, carrying the adsorbed contaminants with them.

- Foam Removal: The foam layer, now concentrated with PFAS, is removed for further treatment or disposal.

Benefits of Foam Fractionation

-

High Efficiency: Studies show that foam fractionation can achieve PFAS removal efficiencies exceeding 90%, making it one of the most effective methods available.

-

Lower Energy Requirements: Compared to traditional methods like activated carbon adsorption, foam fractionation requires less energy, thereby reducing operational costs.

- Versatility: Foam fractionation can be integrated into existing water treatment systems or employed in standalone units, offering flexibility for different applications.

Applications of Foam Fractionation in PFAS Removal

Pilot Studies and Field Deployments

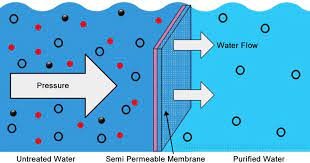

Multiple pilot studies have highlighted foam fractionation’s effectiveness in real-world scenarios. A notable pilot trial conducted in California demonstrated a 95% reduction of PFOS and PFOA concentrations in contaminated groundwater. Results from these studies suggest that foam fractionation can serve as a viable pre-treatment step prior to advanced oxidation processes (AOP) or reverse osmosis systems, further enhancing overall treatment efficacy.

Municipal Water Treatment Facilities

As municipalities adapt to evolving PFAS regulations, many are considering foam fractionation as a core technology in their water treatment arsenals. With the capability to process large volumes efficiently, foam fractionation can be a scalable solution for treating municipal water supplies. Experts predict that by 2027, at least 30% of U.S. municipal plants will incorporate foam fractionation technology in their existing infrastructures.

Challenges in Implementing Foam Fractionation

Scaling and System Design

While foam fractionation shows promise, deploying this technology on a larger scale presents distinct challenges. The design and scaling of foam fractionation systems require a comprehensive understanding of hydrodynamics, bubble characteristics, and the unique properties of the contaminants involved.

Chemical Interferences

Some water matrices may contain competing surfactants or organic compounds that can inhibit the foam fractionation process. Ongoing research focuses on developing pretreatment strategies to mitigate these interferences, ensuring the process’s reliability across various water sources.

Cost Considerations

Although foam fractionation is generally more cost-effective than other removal technologies, initial capital investments for equipment and system modifications can be a barrier for smaller municipalities or facilities. To meet these costs, many facilities are actively seeking federal and state grants aimed at enhancing PFAS removal capabilities.

Future Directions in Foam Fractionation Research

Innovations in Efficiency

Researchers are exploring novel ways to enhance the efficiency of foam fractionation systems through the use of nanomaterials and surfactants designed specifically for PFAS removal. These innovations are expected to increase removal rates and reduce operational costs.

Integration with Other Treatment Methods

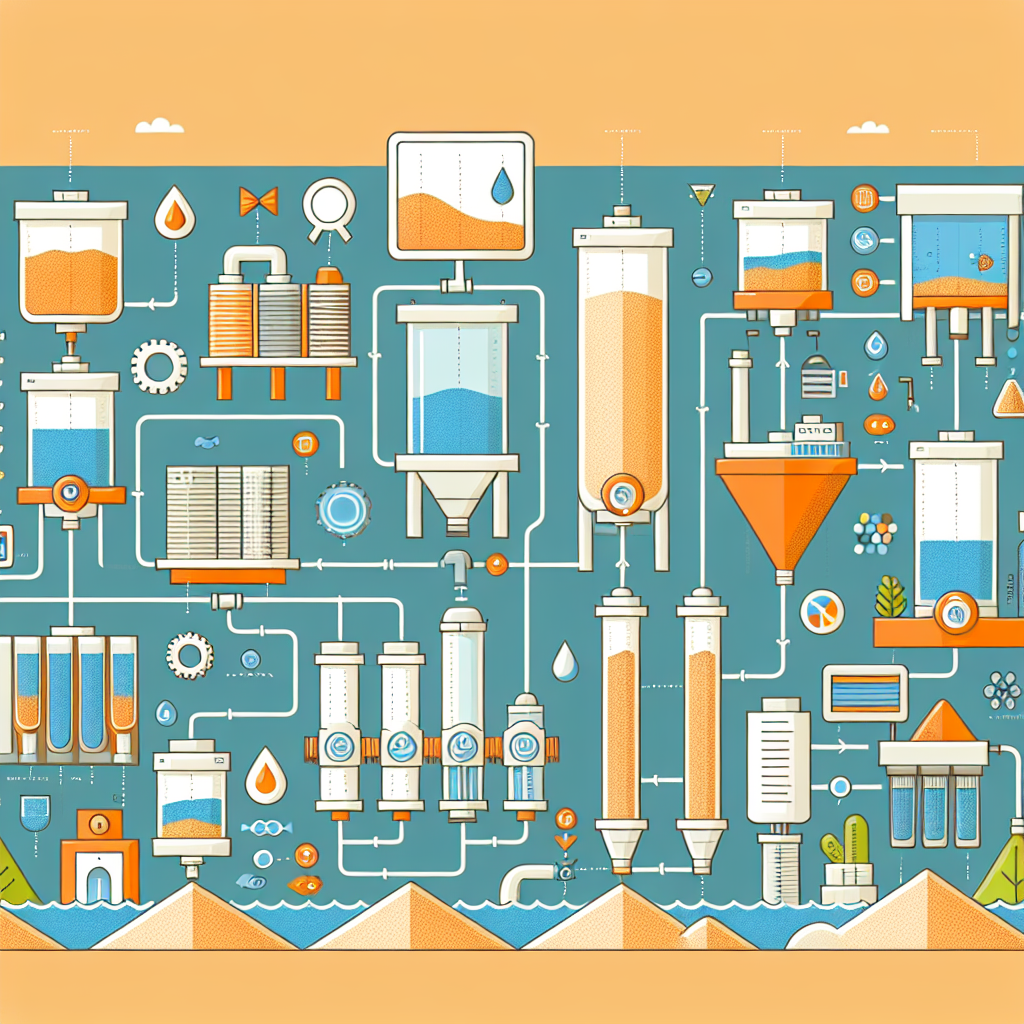

Future developments may also focus on the integration of foam fractionation with other treatment methods, such as electrochemical oxidation or membrane filtration. By creating a multi-barrier system, municipalities can optimize overall PFAS reduction, meeting regulatory requirements more effectively.

Conclusion

Foam fractionation presents a promising solution to the complex challenge of PFAS contamination in water. As municipalities grapple with stricter regulations and increasing public concern, this innovative technology offers a high-efficiency, sustainable approach to enhancing water treatment processes. While challenges remain regarding scalability, cost, and chemical interferences, continued research and development could position foam fractionation as a cornerstone technology in the fight against PFAS contamination.

With the demand for effective water treatment solutions on the rise, now is the time for water treatment professionals and municipal directors to consider foam fractionation as a key strategy in their efforts to safeguard public health and the environment.

source https://www.waterandwastewater.com/foam-fractionation-for-pfas/