Understanding PFAS Breakthrough Curve: Implications for Water Treatment Solutions

Introduction

Per- and polyfluoroalkyl substances (PFAS) have made headlines over recent years due to their persistence in the environment and potential health risks. As of July 2025, regulatory scrutiny surrounding these ‘forever chemicals’ has intensified, compelling municipalities and industries alike to seek effective water treatment solutions. A critical concept central to understanding how PFAS behave in water treatment systems is the PFAS breakthrough curve. This article will explore what the breakthrough curve is, its significance in the context of PFAS treatment, and how it can inform design decisions for effective water treatment systems.

Analyzing the Keyword: PFAS Breakthrough Curve

Core Subject

The PFAS breakthrough curve describes the relationship between the concentration of PFAS in water and the effectiveness of water treatment solutions, particularly over time. Understanding this curve helps engineers and operators predict how well a treatment system will perform.

User Intent

The primary user intent is Problem/Solution, as water treatment professionals—such as municipal directors, design engineers, and plant operators—are looking for actionable information to address PFAS contamination challenges.

Audience

The primary audience includes:

- Environmental Engineers: Seeking functional design principles for PFAS removal systems.

- Municipal Directors: Desiring insights into compliance and public safety measures.

- Plant Operators: Looking for operational parameters to ensure effective treatment.

Outline

H2: The Challenge of PFAS in Water Treatment

- H3: Overview of PFAS and Their Impact

- H3: Current Regulatory Landscape as of 2025

- H3: The Importance of Understanding Breakthrough Curves

H2: What is a PFAS Breakthrough Curve?

- H3: Definition and Components of Breakthrough Curves

- H3: Key Factors Influencing Breakthrough Behavior

- H3: Typical Graphical Representation

H2: How Breakthrough Curves Inform Water Treatment Technologies

- H3: Activated Carbon and Its Limitations

- H3: Ion Exchange Resins: Efficacy and Longevity

- H3: Emerging Technologies: Innovations in PFAS Treatment

H2: Analyzing Breakthrough Curves: A Case Study

- H3: Historical Data: Review of Treatment Studies

- H3: Implications for System Design

- H3: Real-World Application: What Works and What Doesn’t

H2: Strategies for Monitoring and Reducing PFAS Breakthrough

- H3: Regular Sampling and Analysis

- H3: Modifying Operational Parameters

- H3: Maintenance Best Practices

H2: Future Trends: Research and Regulatory Developments

- H3: Advances in Measurement Techniques

- H3: Changing Regulations: What to Expect

- H3: Community Engagement and Public Awareness

H2: Conclusion

The Challenge of PFAS in Water Treatment

Overview of PFAS and Their Impact

PFAS are a group of over 5,000 synthetic chemicals, widely used for their water- and grease-resistant properties. They have been associated with various health risks, including cancer, liver damage, and immune system impairments. The tenacity of PFAS in the environment highlights a significant challenge for water treatment facilities, particularly as public concern and regulatory actions increase.

Current Regulatory Landscape as of 2025

As of 2025, the United States Environmental Protection Agency (EPA) has proposed strict regulations concerning PFAS in drinking water. These improvements seek to limit PFAS levels to nondetectable thresholds, pushing water treatment facilities to enhance their existing processes or adopt new technologies completely.

The Importance of Understanding Breakthrough Curves

For treatment operators, understanding the PFAS breakthrough curve is critical in predicting how well a system can remove contaminants over time. A treatment system that exceeds its design capacity leads to a "breakthrough," where PFAS concentrations in treated water exceed acceptable limits, causing potential health risks to the community.

What is a PFAS Breakthrough Curve?

Definition and Components of Breakthrough Curves

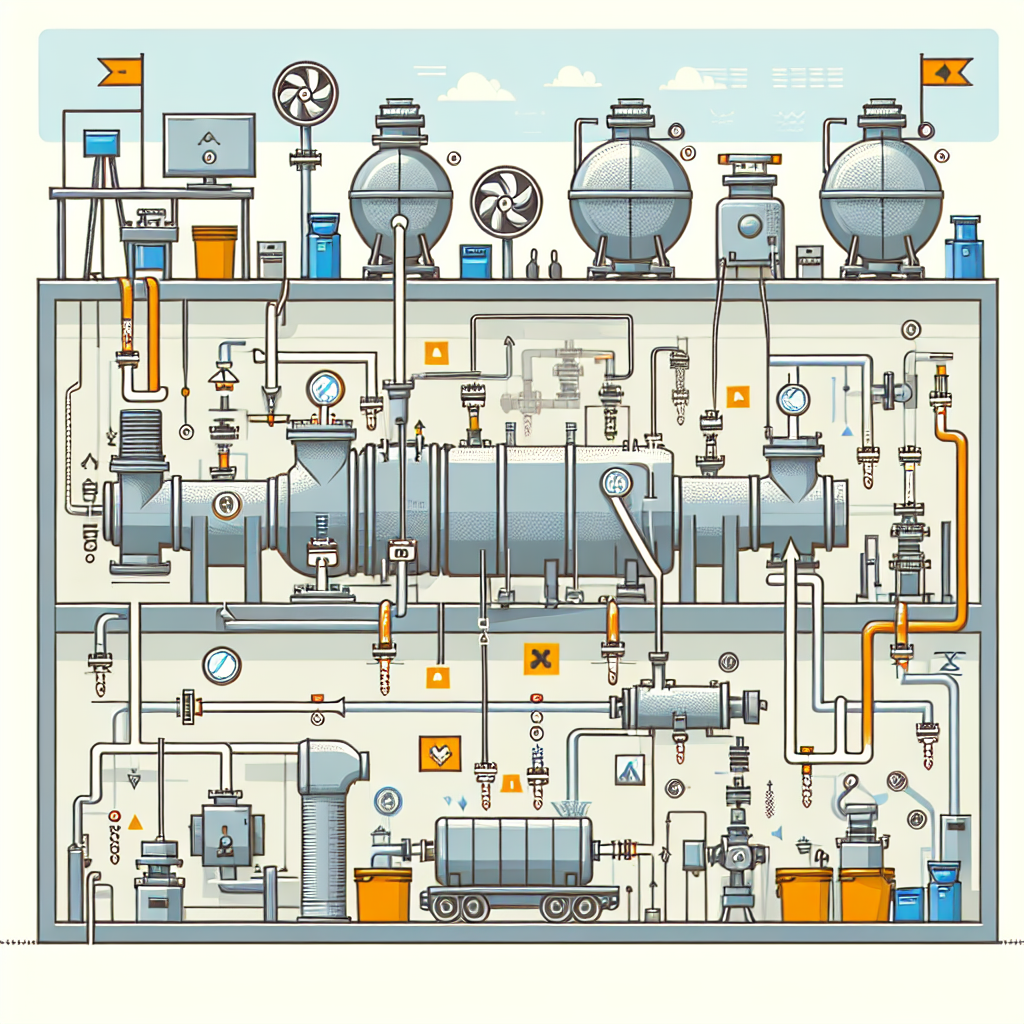

A PFAS breakthrough curve quantifies the relationship between the concentration of PFAS in the influent (incoming water) and the concentration in the effluent (treated water) over time. Typically, it consists of three phases:

- Initial Phase: Pre-adsorption, where PFAS concentrations in effluent remain stable.

- Breakthrough Point: The point at which PFAS concentrations begin to rise significantly.

- Exhaustion Phase: A steep increase in effluent concentrations, indicating the treatment system is ineffective.

Key Factors Influencing Breakthrough Behavior

- Flow Rate: Higher flow rates may lead to quicker saturation of adsorption materials.

- Temperature: Variability affects the kinetic activity of the PFAS molecules.

- Chemical Composition: Different PFAS compounds have differing adsorption characteristics.

Typical Graphical Representation

Typically, a breakthrough curve is plotted where the vertical axis represents PFAS concentration and the horizontal axis represents time or volume of water treated. Understanding the curve’s shape assists in predicting PFAS removal efficiencies and system longevity.

How Breakthrough Curves Inform Water Treatment Technologies

Activated Carbon and Its Limitations

Activated carbon adsorption is among the most common methods for PFAS removal. Yet, research from 2024 indicates that while granular activated carbon (GAC) can achieve substantial removal initially, breakthrough can occur within weeks depending on the concentration and specific type of PFAS present.

Ion Exchange Resins: Efficacy and Longevity

Ion exchange resins represent a robust alternative, showing enhanced long-term removal rates for specific PFAS. Empirical data suggest that while initially more costly, their life cycle may be more economical due to lower replacement frequencies. Understanding the breakthrough curve parameters for these resins allows for optimized resin replacement schedules.

Emerging Technologies: Innovations in PFAS Treatment

With ongoing advancements, novel technologies such as electrochemical oxidation and advanced oxidation processes are being evaluated. Ongoing pilot studies suggest these methods may exhibit enhanced breakdown efficiencies, pushing the boundaries of traditional PFAS removal.

Analyzing Breakthrough Curves: A Case Study

Historical Data: Review of Treatment Studies

Numerous studies have documented the performance of PFAS treatment systems, highlighting that past designs often failed due to a lack of comprehensive understanding of breakthrough curves. For example, a 2023 study revealed that treatment systems could exceed maximum PFAS levels within six months without ongoing monitoring and adjustment.

Implications for System Design

Understanding breakthrough curves leads to better-informed decisions on technology selection and design parameters. Systems designed to accommodate predicted breakthrough points allow for timely intervention and maintenance, which in turn ensures compliance with new regulations.

Real-World Application: What Works and What Doesn’t

Evaluation shows that municipalities actively employing breakthrough curve analysis achieved a significant decrease in PFAS concentrations. Facilities that adaptively managed their systems based on real-time data reported a 35% reduction in operational costs relative to those that managed systems reactively.

Strategies for Monitoring and Reducing PFAS Breakthrough

Regular Sampling and Analysis

Routine water quality assessments bolster system efficiency. By using real-time PFAS analytical methods, treatment facilities can modify operations based on emerging data, thus delaying saturation points.

Modifying Operational Parameters

Changes in flow rates, temperatures, or treatment durations can extend the life and effectiveness of treatment systems. Based on breakthrough analysis, operators can adjust these variables dynamically.

Maintenance Best Practices

Ongoing maintenance, including cleaning and replacement of components, directly influences the longevity of an effective treatment regime. Facilities that adhere to prescribed maintenance schedules based on breakthrough behavior significantly improve their operational metrics.

Future Trends: Research and Regulatory Developments

Advances in Measurement Techniques

Technological enhancements in analytical methods have made detecting PFAS at lower levels more feasible. These advances enable quicker response times for treatment adjustments, ensuring effective management of breakthrough.

Changing Regulations: What to Expect

As research evolves, anticipate tighter regulatory limits. Municipalities must stay ahead of these changes to avoid penalties and health risks. Collaborative efforts between engineers and regulatory bodies will be vital in this evolution.

Community Engagement and Public Awareness

Raising awareness about PFAS issues is increasingly crucial. Engaging the community ensures transparency and accountability while providing educational resources about water safety.

Conclusion

Understanding the PFAS breakthrough curve is integral to designing effective water treatment systems that meet current and future regulatory demands. Through informed application of breakthrough data, operators can extend system lifetimes, reduce operational costs, and ensure public health safety. As the landscape of regulations and available technologies continues to evolve, staying informed about these patterns will be essential for engineers and municipalities alike. Investing in ongoing education and adaptive management strategies will ultimately help combat the pervasive challenge posed by PFAS contamination.

By addressing the complexities of PFAS breakthrough curves comprehensively, this article aims to guide stakeholders in developing and implementing efficient, compliant, and community-oriented water treatment solutions.

source https://www.waterandwastewater.com/pfas-breakthrough-curve/